Secure, Energy preserving, efficient and highest quality

Fibre Board machine:

Fibre Board machine Link here: https://biodegradable-pots.com/pressed-fibre-board-machine/

Construction with natural fibres

Our fiber pressing machine is an ideal solution for construction in fiber-rich countries, enabling the production of eco-friendly building materials from abundant natural resources. It has been used successfully with coconut fiber and can process a wide variety of fibers like jute, hemp, and agricultural residues. The resulting compressed panels are durable, lightweight, and perfect for wall cladding, insulation, ceiling tiles, and furniture, offering a sustainable alternative to traditional materials. This machine empowers local industries to create cost-effective, green construction products while reducing waste and promoting environmental sustainability.

Natural Fibre pot making machine for sale

Coco Premium Pot making machine from various natural fibre. Our secret manufacturing sauce consists out of a very high pressure and duration mechanism, which enables to produce the industries highest quality pots.

TEST – Your Material first before buying the machine (500 g. required)

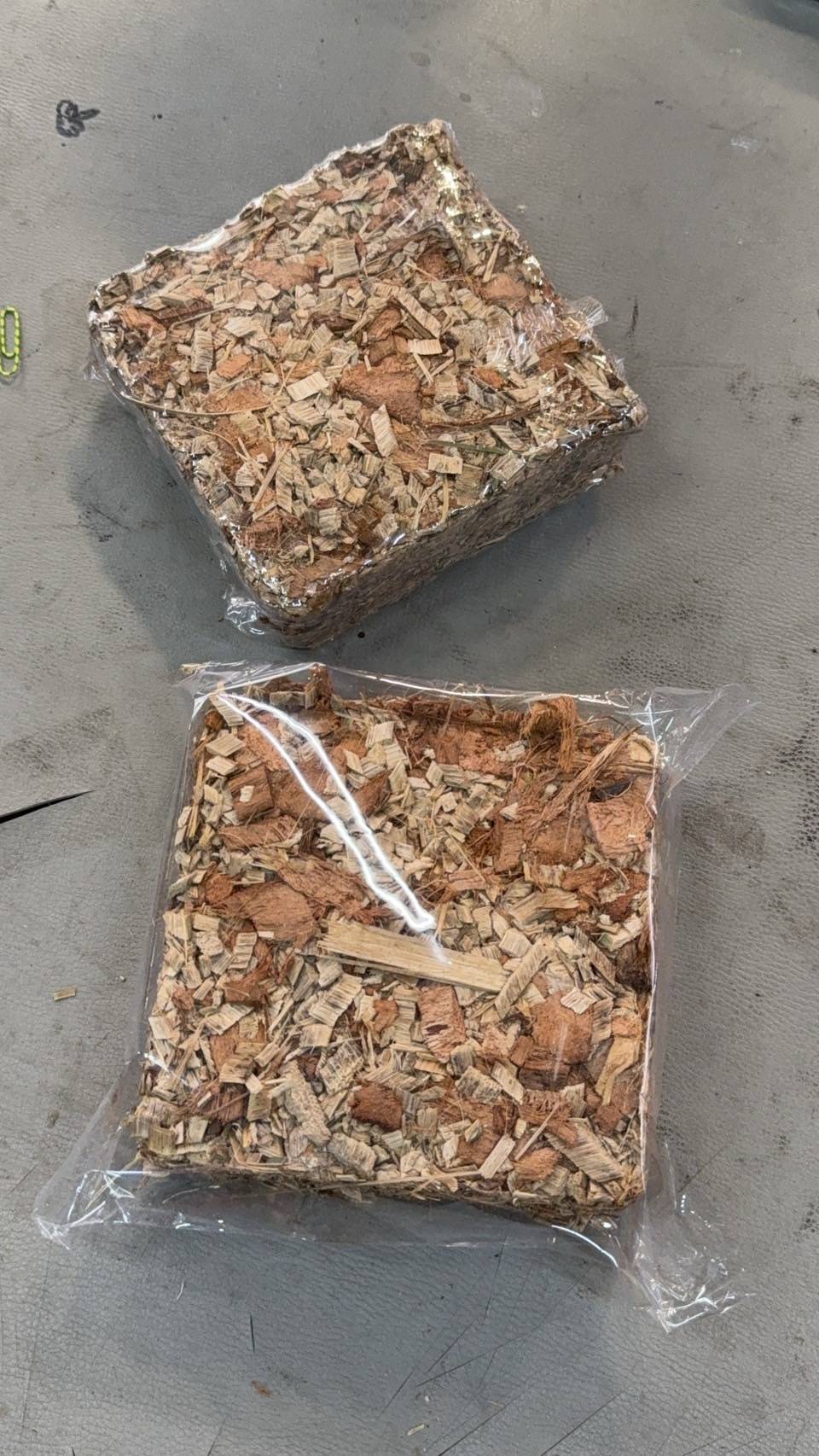

Palm Fibre Brick as fibre material

Whatever material you intend to apply with our machine, test it first and send us a sample, before ordering the machine.

Pot Quality – Low Quality machine vs. High quality machine

Quality from the pot machine, is clearly recognizable by looking closely at the material composition after the pressing process:

Pots from Palm Fibre

Security (Double Secure setup for employees)

Secured by a double activation procedure, so body parts like hands and fingers are impossible to injure.

Pot Making Machine Pressure Gauge

Attached to hydraulic pump

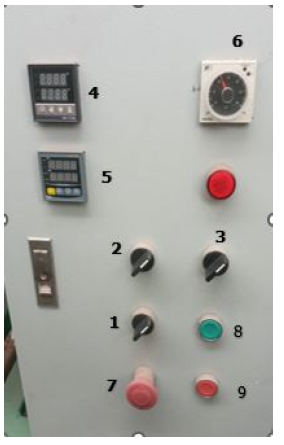

Multiple Feature Control Board

Coir Pot Making Machine manufacturer process

The setup of a coir pot machine consists of the pressure unit and the mold. Power Plugs will be adapted to country specific electricity requirements.

Coco Pot Maker Control Panel step 1 to 9

High Performance Compressor for fast processing

Brand new or Second hand machines available, Machine Specifications

| Production Capacity | 3000 coir pots per month |

|---|---|

| Power Consumption | 1hp |

| Automation Grade | Automatic |

| Material | Steel |

| Phase | 4 phase |

| Raw Material Processed | Coir |

| Power Source | Electric |

| Frequency | 50-60Hz |

| Voltage | 440V |

| Country of Origin | Made in Thailand |

| Heater power | 15 HP |

| Tonnage | 350 kg |

| Ampere | 10 |

Production capacity example

An example of following pot measure:

- 13.4cm x 13.6 cm x 9.6 cm

a standard machine, can output 3000 pcs a month or approx. 30 seconds for one pot.

This capacity can be increased significantly, by additional machinery investments accordingly.

Biodegradable Pot Manufacturing machine

Including warranty:

- 2 year warranty on the press kit system

- 1 year electrical warranty

- 1 year warranty on the heating system

Coir pot making machine price

Price for a coir pot machine vary depending on the following criterias:

- Monthly production quantity required

- Automation grade

- Size of the Pot(mold)

Shipping Requirements

- Must be on a parent and can’t have objects on object parent

- No dangerous goods contained

- Electricity: Single phase electricity, but can be adjusted depending on country

Certifications and standards

Guaranteed by the highest esteemed factory certifications in the world

- ISO

- IAF

- TUV

- IATF

Pallet Loading Details

- Weight

360 kg. - Measurement

73x73x210 cm.

Automatic pot making machine

The leading Coir Pot Making Machine manufacturer

Bio Pot Machine in progress

Questions and answers Pot manufacturing machine

- What is the difference between displays ‘a’ and ‘b’?

A is the upper mold heat display, B is the lower mold heat display. - Can the operating temperature be changed to other values using one or both of these displays, or can the mold only be set to 130-150 °C?

Can adjust the temperature on the display screen - Can the press be used without the heater being switched on?

Yes it can - If the pressure gauge/display is something that can be easily added?

There is already a pressure gauge on the hydraulic pump. - Do the technical specifications of the hydraulic press mention that pressure the press exerts? This value is often known if a hydraulic press is bought off the shelf.

15 Tons - Are you using latex as the adhesive and if so, how much do you dilute the latex before spraying?

LATEX is 20% , Water is 80% - Have you tried pressing the coconut fibre without adding the latex (or other adhesive)? If so, what happens? Does it stick together or just fall apart?

If not using glue The pots will not stick together. We have tried with different types of glue. The best is LATEX and rubber glue. - Do you use any safety shields when operating the press?

We only use normal apron because the machine is not dangerous. - max height 20 cm

- Max width = 25 cm

Pot Making machine, ready for shipping